In the bustling heart of factories, pakhuise, skeepswerwe, and construction sites, a silent giant often shoulders the heaviest burdens. Meet the Bridge Crane System – the workhorse of material handling, essential for lifting, moving, and positioning massive loads with precision and efficiency. If you’ve ever marveled at how tons of steel, machinery, or raw materials glide effortlessly through a facility, chances are a brugkraan was the invisible force behind it.

At its core, a bridge crane is an overhead lifting system that operates on a runway structure. Picture this:

1. The Runway: Two parallel rails fixed high above the floor, typically mounted to the building’s support columns or on freestanding support structures.

2. The Bridge: This is the horizontal beam (or beams – often called girders) that spans the width of the bay, traveling along the runway rails. It forms the literal “bridge” across the workspace.

3. The Hoist and Trolley: Mounted on the bridge girder(s) is a trolley. This trolley moves side-to-side across the length of the bridge. Attached to the trolley is the hoist – the powerhouse that actually lifts and lowers the load via its hook, magnet, or specialized lifting attachment.

4. The Control System: Operators control the crane via pendant (a hanging control box), radio remote, or from an operator cabin mounted on the crane itself. Controls manage all three axes of movement: bridge travel (along the runway), trolley travel (across the bridge), and hoist movement (up/down).

This unique configuration grants the bridge crane its superpower: unparalleled coverage of a rectangular area.

Bridge Travel: Moves the entire crane structure (bridge, trollie, and hoist) along the length of the building (X-axis).

Trolley Travel: Moves the hoist laterally across the width of the bridge (Y-axis).

Hoist Movement: Raises and lowers the load vertically (Z-axis).

This combination provides full 3D positioning within the crane’s designated work envelope – the area beneath the runway and between the runway rails.

1. Maximized Floor Space: By operating overhead, bridge cranes free up valuable floor space below. No aisles for forklifts are blocked; machinery and storage can utilize the entire area.

2. Heavy Lifting Capacity: Engineered for demanding tasks, bridge cranes handle capacities ranging from a few tons to several hundred tons with ease and safety.

3. Precision Handling: Fine control allows operators to position extremely heavy or delicate loads with pinpoint accuracy – crucial for assembly lines, machine installation, or handling sensitive materials.

4. Safety: Properly designed and operated bridge cranes significantly reduce risks associated with manual lifting or ground-based equipment maneuvering heavy loads near personnel. Features like overload protection and limit switches enhance safety.

5. Versatility: They can be equipped with various hoists (wire rope, chain), hooks, magnete, grabs, or specialized lifting fixtures to handle virtually any load type – from steel coils and machinery to shipping containers and castings.

6. Durability & Longevity: Built from robust steel and designed for industrial environments, a well-maintained bridge crane provides decades of reliable service.

7. Improved Efficiency & Productivity: Streamlining the movement of heavy materials drastically reduces handling time, minimizes product damage, and speeds up production processes.

Manufacturing: Moving raw materials, positioning components on assembly lines, installing heavy machinery.

Warehousing & Distribution: Handling large pallets, loading/unloading trucks (especially with larger systems).

Metal Fabrication: Lifting steel plates, beams, and finished structures.

Foundries: Handling molds, cores, and molten metal containers (with specialized cranes).

Shipyards: Building and repairing ships, moving massive sections and engines.

Power Plants: Installing and maintaining turbines, kragers, and transformers.

Aerospace: Maneuvering large aircraft components.

Scrap Yards: Handling and sorting recycled materials.

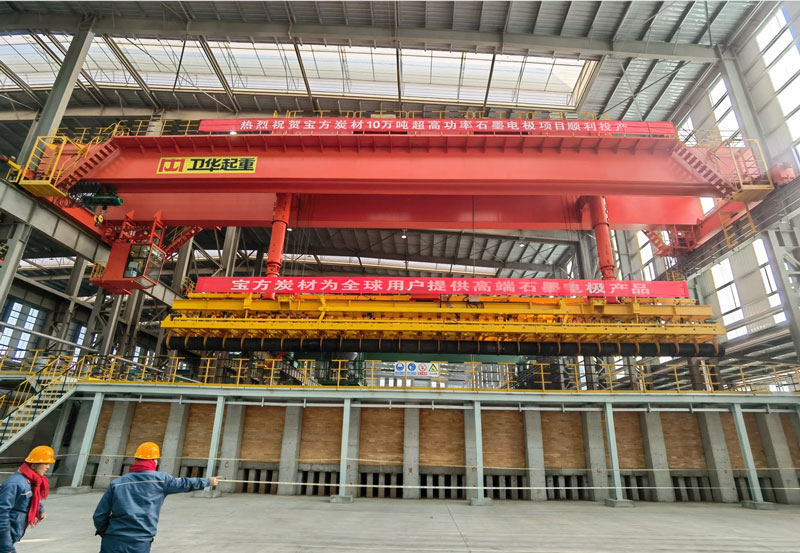

Top Running: The bridge runs on rails mounted on top of the runway beams. Highest lifting height and greatest load capacity.

Under Running (Underhung): The bridge wheels run on the bottom flange of the runway beams, which are typically supported by the roof structure. Ideal for lighter to medium capacities and facilities where headroom is a constraint.

Single Girder: One main bridge beam. Cost-effective for lighter loads and shorter spans.

Double Girder: Two main bridge beams. Required for heavier loads, longer spans, and often allows for higher lifting heights and the use of specialized trolleys/hoists.

Gantry Crane: A variation where the bridge is supported by rigid legs that run on rails or wheels on the ground, making it mobile and independent of the building structure. Often used outdoors or in areas without overhead support.

Bridge crane systems continue to evolve. Integration with automation and the Internet of Things (IoT) is becoming more common. Features like automated guided crane systems (AGCs), remote monitoring, predictive maintenance sensors, and enhanced safety systems (collision avoidance, anti-sway technology) are pushing these industrial giants into a smarter, more connected future.

The bridge crane system is far more than just steel beams and motors. It’s the backbone of efficient, safe, and powerful material handling in countless industries. By mastering the space above, it unlocks productivity and capability on the floor below. Next time you see one in action, take a moment to appreciate the engineering marvel effortlessly orchestrating the movement of tons – the true unsung hero of the industrial world.

Q1: What’s the difference between a bridge crane and an overhead crane?

A: The terms are often used interchangeably. Technically, bridge crane refers to the crane’s structure (bridge girder + hyskraan), while overhead crane describes its installation type (mounted overhead on runways). All bridge cranes are overhead cranes, but not all overhead cranes are bridge cranes (Bv., jib cranes are also overhead).

Q2: How much weight can a bridge crane lift?

A: Capacity ranges from 1 ton to 500+ ton:

| Single Girder | Double Girder |

| ✓ Lower cost | ✓ Higher capacity (25+ ton) |

| ✓ Spans ≤ 30m | ✓ Longer spans (30m+) |

| ✓ Lighter loads (≤20 tons) | ✓ Higher hook height |

| ✓ Easier maintenance | ✓ Supports specialized trolleys |

Los u opmerking hier