Our Address:

- No. 18 Shanhai Avenue, Changyuan City, Henan Province, China.

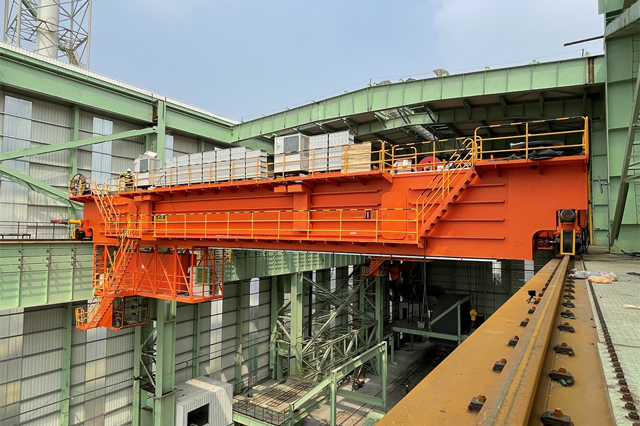

Our 25-ton double girder overhead crane is engineered for industrial environments where moving massive, heavy loads with utmost reliability, safety, and efficiency is paramount. This robust material handling solution is designed to optimize workflow in manufacturing plants, steel service centers, shipping yards, power generation facilities, and large-scale warehouse operations. It represents the perfect synergy of superior structural integrity, advanced control systems, and operator-focused design, ensuring seamless integration into your most demanding production cycles.

| Parameter | Specification |

| Capacity | 25 Tons (50,000 lbs / 22,680 kg) |

| Span | Customizable to your bay width (e.g., 50ft to 100ft+) |

| Lifting Height | Customizable (e.g., 20ft to 60ft+) |

| Class of Service | Typically Class D (Heavy Duty) or Class E (Severe Duty) |

| Operating Duty | FEM 1Am / 2m / 3m or H3/H4 (equivalent to CMAA Class D/E) |

| Control | Pendant Control (Standard), Radio Remote (Optional) |

| Power Supply | 3-Phase, 480V/60Hz (or as per local requirement) |

| Ambient Temperature | -20°C to +40°C (Standard) |

| Travel Speeds | Customizable (e.g., Hoist: 0.5-8 m/min, Bridge: 10-32 m/min) |

This 25-ton overhead crane is ideal for a vast range of heavy-lifting tasks, including:

1. Handling large metal coils, sheets, and plates in steel mills.

2. Moving heavy machinery and components in fabrication and assembly shops.

3. Loading and unloading large containers and heavy cargo in logistics hubs.

4. Maintenance and repair tasks in power plants and large industrial facilities.

5. Storing and retrieving massive items in high-bay warehouses.

We understand that every facility is unique. This crane can be fully customized to your specific requirements, including:

1. Span, lifting height, and runway design.

2. Control options (Pendant, Cab, or Radio Remote).

3. Special hooks (C-hooks, coil lifts, magnets, vacuum lifters).

4. Environmental adaptations (explosion-proof, high-temperature, or corrosion-resistant coatings).

5. Automation and integration with existing warehouse management systems (WMS).

Our service package includes professional installation, commissioning, comprehensive operator training, and a dedicated after-sales support network to ensure your crane operates at peak performance for years to come.

Investing in our 25-ton overhead crane means investing in productivity, safety, and the long-term growth of your operations. It is a dependable workhorse built to withstand the rigors of heavy industry while providing the precision control needed for delicate positioning tasks.

Contact us today for a detailed quotation and engineering consultation tailored to your facility’s layout and material handling needs.