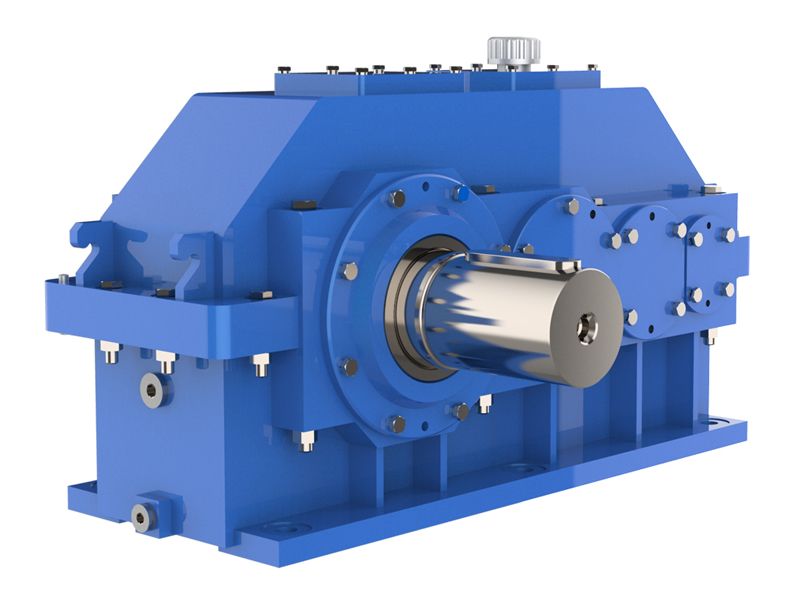

Weihua’s EOT crane gearbox is a core component designed to deliver precise, powerful, and reliable motion for electric overhead traveling cranes (EOT cranes). Engineered with advanced gear technology and built using high-grade materials, this gearbox ensures long-lasting performance and smooth operation even under heavy-duty industrial conditions.

| Tham số | Hoist Gearbox Range | Trolley Travel Gearbox Range | Notes |

| Power Rating | 3 kW – 400 kW | 1.5 kW – 90 kW | Dependent on duty cycle (FEM 1M to 4M) |

| Output Torque (Nominal) | 1,000 Nm – 200,000 Nm | 500 Nm – 30,000 Nm | Peak torque capacity 2.5× nominal |

| Reduction Ratio (i) | 10:1 - 200:1 | 5:1 - 80:1 | Custom ratios available |

| Efficiency | 94% - 98% | 92% - 96% | Helical/hardened helical gear design |

| Input Speed | 750 / 1,000 / 1,500 / 1,800 RPM | 750 / 1,000 / 1,500 RPM | Compatible with IEC motors |

| Mounting Type | Foot-mounted, Flange-mounted (B5/B14) | Foot-mounted, Flange-mounted | Shaft-mounted options for trolleys |

| Gear Type | Helical / Hardened Helical (HG Series) | Helical / Hardened Helical | HG Series: Case-hardened (HRC 58-62) |

| Housing Material | Cast Iron (GGG50) / Welded Steel | Cast Iron / Welded Steel | IP55 protection standard |

| Lubrication | Synthetic EP Gear Oil (ISO VG 150-320) | Synthetic EP Gear Oil (ISO VG 100-220) | Splash lubrication + sealed bearings |

| Operating Temp. | -20°C to +80°C | -20°C to +80°C | Forced cooling available for >80°C |

| Service Factor | 1.25 - 2.0 (per FEM/ISO) | 1.1 - 1.6 (per FEM/ISO) | Based on FEM 1.001/ISO 6336 |

| Backlash | ≤ 120 arcmin (P < 100 kW)

≤ 100 arcmin (P ≥ 100 kW) |

≤ 100 arcmin | Precision-ground for smooth reversing |

| Noise Level | ≤ 75 dB(A) @ 1m distance | ≤ 70 dB(A) @ 1m distance | Measured under full load |

| Safety Factor (Bending) | ≥ 2.0 | ≥ 1.8 | Nữ 1.001 / AGMA 2001-D04 |

| Safety Factor (Contact) | ≥ 1.5 | ≥ 1.4 | |

| Standards Compliance | ISO 6336, Nữ 1.001, TỪ 3990, AGMA 6010 | ISO 6336, Nữ 1.001 | CMAA/AS certifications on request |

1. Standard Helical Series

Applications: General workshop cranes, warehouses.

Max. Torque: 50,000 Nm (hoist), 15,000 Nm (trolley).

2. Hardened Helical (HG) Series

Applications: Steel mills, foundries, mining.

Surface Hardness: HRC 58-62.

Max. Torque: 200,000 Nm (hoist), 30,000 Nm (trolley).

3. Customization Support

| Model Size | Weight (kg) | Flange Dia. (mm) | Output Shaft Dia. (mm) |

| Small (≤30kW) | 50 - 200 | 200 - 400 | 40 - 80 |

| Medium (≤160kW) | 250 - 900 | 450 - 800 | 90 - 160 |

| Large (≤400kW) | 1,000 - 4,500 | 850 - 1,500 | 180 - 300 |

Notes:

1. Duty Cycle: Designed for FEM 1M (light) to 4M (severe duty).

2. VF Drive Compatibility: Optimized for inverter-driven motors (5-100 Hz).

3. Testing: 100% run-tested under load; vibration analysis per ISO 10816.

4. Lead Time: 15–30 days for standard models; 45–60 days for customized units.

Weihha EOT crane gearboxes are not just components; they are precision power transmission systems built to handle the rigorous demands of:

1. High starting torque for lifting heavy loads smoothly.

2. Frequent start-stop cycles inherent in crane operation.

3. Variable speeds and precise positioning control.

4. Exposure to dust, moisture, and temperature fluctuations.

1. Robust Construction & Premium Materials: Manufactured using high-strength alloy steels for gears and shafts, housed in rigid, high-grade cast iron or welded steel casings. This ensures exceptional resistance to shock loads, bending moments, and wear.

2. Advanced Helical / Hardened Helical Gearing: Our standard helical gear design provides smoother, quieter operation and higher torque transmission efficiency compared to spur gears. For ultimate durability in extreme conditions, Weihua offers hardened and ground helical gears, significantly increasing surface hardness and lifespan.

3. Optimized Power Transmission & Efficiency: Precisely engineered tooth profiles and meticulous manufacturing minimize power loss, translating to lower energy consumption and reduced operating costs over the crane’s lifetime.

4. Superior Sealing & Lubrication: Multi-layered sealing systems (lip seals, labyrinth seals) effectively prevent lubricant leakage and ingress of contaminants. Optimized lubrication channels ensure all critical components are adequately lubricated, even under heavy loads and inclines.

5. High Reliability & Extended Service Life: Rigorous quality control, advanced design simulation (FEA), and stringent testing protocols guarantee exceptional reliability. Weihua gearboxes are built for longevity, minimizing unplanned downtime and maintenance costs.

6. Smooth & Quiet Operation: The helical gear design combined with precision machining results in significantly reduced vibration and noise levels, contributing to a better working environment.

7. Comprehensive Safety Integration: Designed as a critical safety component, our gearboxes contribute to the overall safe operation of the crane, ensuring controlled motion and load handling under all specified conditions.

8. Standard Compliance: Designed and manufactured to meet or exceed international standards relevant to crane safety and performance (such as ISO, Nữ, TỪ, CMAA, AS).

9. Extensive Customization: Weihua understands that every application is unique. We offer customized EOT crane gearbox solutions tailored to specific requirements, including:

Various reduction ratios

Multiple mounting configurations (foot-mounted, flange-mounted)

Input/output shaft sizes and types

Specific torque and power ratings

Integration with different motor types (e.g., AC induction, variable frequency drive compatible)

Weihha EOT crane gearboxes are integral components driving both the hoisting mechanism (lifting/lowering the load) and the trolley travel mechanism (moving the hoist across the bridge) in diverse settings:

Steel Mills & Foundries

Power Plants

Shipyards

Mining & Quarrying

Heavy Machinery Manufacturing

Warehouses & Logistics Centers

Ports & Terminals

Construction Sites

1. Proven Expertise: Decades of dedicated crane engineering experience.

2. Vertical Integration: Control over design, material sourcing, manufacturing, and testing ensures consistent quality.

3. Global Support Network: Access to technical support, genuine spare parts, and service worldwide.

4. Focus on Value: Delivering the optimal balance of performance, độ bền, and total cost of ownership.

Invest in the Powerhouse of Your Crane.

Choose Weihua EOT Crane Gearboxes – the reliable, efficient, and durable solution engineered to keep your overhead lifting operations running smoothly and productively, day in and day out.

Để lại bình luận của bạn ở đây