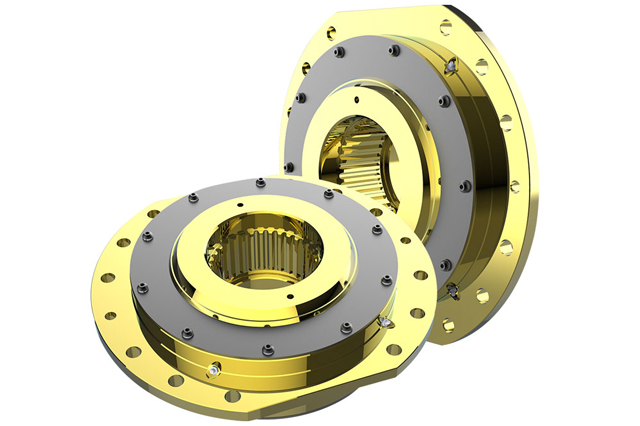

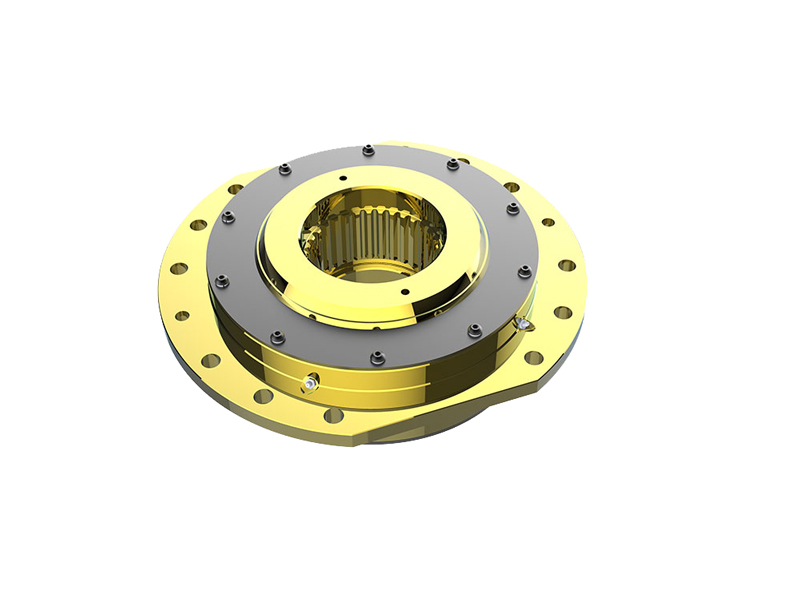

Weihua’s crane reel coupling is a precision-engineered component designed to ensure efficient and secure torque transmission between crane drums and motor drives in reel systems. It plays a crucial role in synchronizing the rotational motion of cable reels, allowing for smooth, controlled winding and unwinding of electrical cables or hoses on cranes.

1. High Torque Capacity: Designed to handle the demanding loads of reel operations, ensuring consistent performance during long-duty cycles.

2. Durable Construction: Manufactured with high-strength alloy steel or cast iron, Weihua’s reel couplings offer superior resistance to wear, fatigue, and environmental stress.

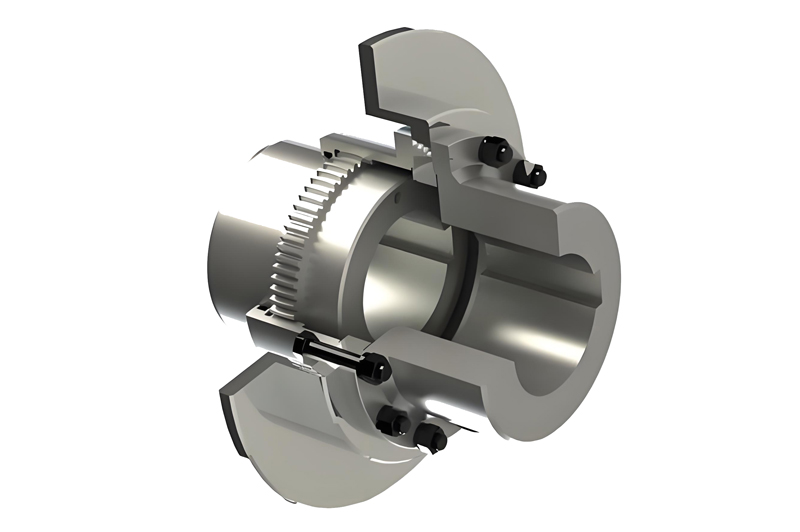

3. Misalignment Compensation: The coupling allows for axial, radial, and angular misalignments, reducing strain on reel bearings and prolonging equipment life.

4. Corrosion-Resistant Finishing: Special coatings and treatments are available for harsh environments, including marine, port, and outdoor construction sites.

5. Easy Installation and Maintenance: Modular design allows for quick assembly and disassembly, minimizing crane downtime during service.

| Parameter | Specification |

| Torque Range | 500 – 50,000 Nm |

| Shaft Diameter | 25 mm – 200 mm |

| Material | Cast iron, Alloy steel, Customizable |

| Max Speed | Up to 3000 RPM |

| Operating Temperature | -20°C to +80°C |

| Misalignment Capacity | Axial ±1mm, Angular ±1.5°, Radial ±0.5mm |

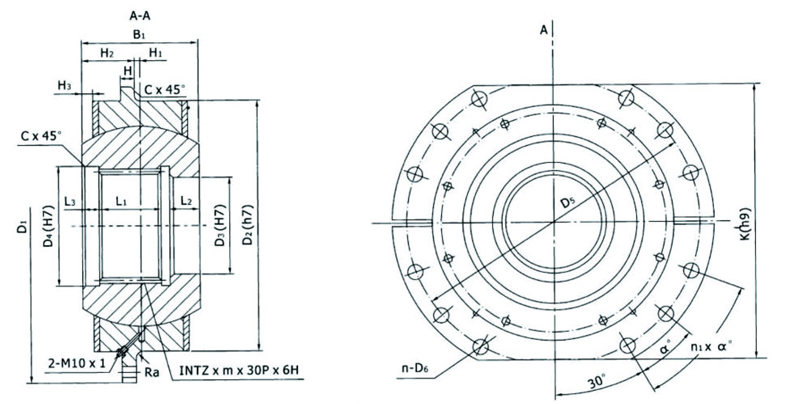

1. Nominal torque range: 710 Nm to 100,000 Nm

2. Permissible speed: 660–3,780 rpm

3. Weight: 7.8 kg to 540 kg, depending on model

4. Shaft fit: Tailored to project-specific shaft diameters via CNC machining to meet precision and alignment needs

1. Torque & speed: Define working torque and choose nominal torque with safety margin.

2. Misalignment allowance: For cranes with significant misalignment, opt for drum‑gear models.

3. Environment: For extreme conditions—dust, heat—choose sealed variants with high‑grade materials.

4. Maintenance: Gear couplings need periodic lubrication checks; drum‑gear models offer easier sleeve maintenance.

| Advantage | Description |

| Robust torque transfer | Precision gears, hardened surfaces |

| Shock & vibration damping | Curved teeth absorb dynamic stresses |

| Misalignment tolerance | Reduces stress on connected shafts |

| Maintenance-friendly design | Sleeve can be swapped in place |

| High reliability | Sealed lubrication, quality materials |

Considerations:

1. Requires regular lubrication to maintain performance.

2. Higher cost than basic couplings, but justified by durability and uptime.

3. Must be properly sized for torque, speed, alignment, and environmental factors.

Weihua’s crane shaft couplings (including fixed, gear, and drum‑gear types) are engineered for optimal performance in heavy-duty crane applications. They provide steady torque transfer, compensate misalignment, reduce vibration, and ease maintenance—making them ideal for overhead and gantry cranes in demanding environments.

For a tailored quotation or detailed sizing, Weihua offers customizable solutions based on parameters like shaft diameter, torque requirements, permissible misalignment, and working conditions. You can reach out via their contact channels provided on the website.

Leave your Comment here