Nosso endereço:

- Não. 18 Avenida Shanhai, Cidade Changyuan, Província de Henan, China.

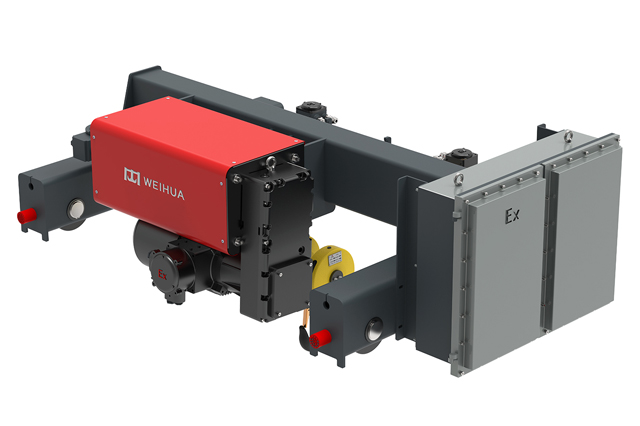

The HB Series Explosion-Proof Electric Hoist is engineered for the most demanding and hazardous industrial environments.

Designed with safety as the paramount priority, this HB series explosion-proof electric hoist ensures reliable and efficient material handling in areas where flammable gases, vapors, dust, or fibers may be present. It combines superior explosion-proof technology with high-performance lifting capabilities to protect both your personnel and your assets.

Certified Explosion-Proof Protection:

The hoist’s critical components—including the motor, control box, emergency limit switch, and electrical enclosures—are encased in specially designed housings that prevent any internal spark or high surface temperature from igniting the surrounding atmosphere.

Complies with international explosion-proof standards such as ATEX (for Europe) and IECEx, often certified for Zones 1, 2, 21, e 22.

Robust and Durable Construction:

Built with high-strength materials to withstand corrosive and harsh environments. Key components are often made of non-sparking materials like copper alloys or stainless steel to prevent ignition risks.

Recursos de segurança aprimorados:

Equipped with a dual braking system featuring an independent mechanical load brake and an electromagnetic brake, providing fail-safe operation and precise load control.

Includes upper and lower limit switches to automatically stop the hoist at its maximum and minimum heights, preventing overtravel and accidents.

Thermal protection in the motor guards against overload and phase failure.

High Performance and Efficiency:

Features a high-torque, explosion-proof motor that ensures smooth start-up, stable operation, and powerful lifting capacity.

Low Headroom design maximizes lifting height in confined spaces.

Precision-machined gearing ensures smooth and quiet operation with minimal vibration.

User-Friendly Operation:

Operated via a low-voltage, explosion-proof pendant control station with clearly marked buttons for up, down, and traverse directions. The control is ergonomically designed and responsive.

Options for radio remote control are available for added operator safety and convenience.

Low Maintenance:

Sealed components protect against dust and moisture ingress, reducing wear and tear and extending the service interval.

Designed for easy inspection and maintenance to minimize downtime.

Note: Parameters are typical and may vary by specific model and manufacturer. Always consult the official product manual.

| Parâmetro | Especificação |

| Capacidade | 1 ton, 2 ton, 3 ton, 5 ton, 10 ton, 20 ton |

| Altura de elevação | 6eu, 9eu, 12eu, 18eu, 24eu, 30eu |

| Velocidade de levantamento | 8/2 m/meu (Dual Speed) |

| Hoisting Motor Power | 1.5 quilowatts – 13 kW |

| Traveling Speed | 20 m/meu (approx.) |

| Work Duty | Class FEM 2m / Class M4 |

| Fonte de energia | 3 Fase, 380V/415V, 50/60 Hz |

| Explosion-Proof Classification | Ex d e mb IIB T4 Gb / Ex tb IIIC T135°C Db |

| Temperatura ambiente | -20°C a +40 °C |

| Protection Rating | IP55 / IP65 |

| Application Zone | Zone 1 & 21, Zone 2 & 22 |

The HB Series Explosion-Proof Electric Hoist is indispensable in industries where the atmosphere has a potential risk of explosion due to the processing, production, or storage of combustible materials.

Oil & Gas: Refineries, offshore platforms, and petrochemical plants for handling equipment and materials near flammable hydrocarbons.

Chemical & Pharmaceutical: Chemical processing plants, paint and coating factories, and pharmaceutical facilities where explosive solvents, powders, or vapors are present.

Mineração (Coal): Coal preparation plants and other areas where combustible coal dust is a significant hazard.

Aerospace & Military: For painting hangars, fuel storage areas, and maintenance facilities involving flammable fluids.

Agriculture & Grain Handling: Grain silos, elevators, and processing plants where highly combustible dust from grain, sugar, or flour is generated.

Manufacturing: Workshops involving flammable metal dust (POR EXEMPLO, magnesium, aluminum), wood dust, or plastic powders.

Wastewater Treatment & Biogas Plants: Areas where methane and other explosive gases can accumulate.

The HB Series Explosion-Proof Electric Hoist is not just a tool but a critical safety system for hazardous area operations. Its certified design, reliable performance, and durable construction make it the ideal choice for industries that cannot compromise on safety. By investing in the HB series, you are investing in the protection of your workforce, your facility, and the continuity of your operations.

Contact us today to discuss your specific requirements and find the perfect explosion-proof lifting solution for your application.