Бүтээгдэхүүний тойм

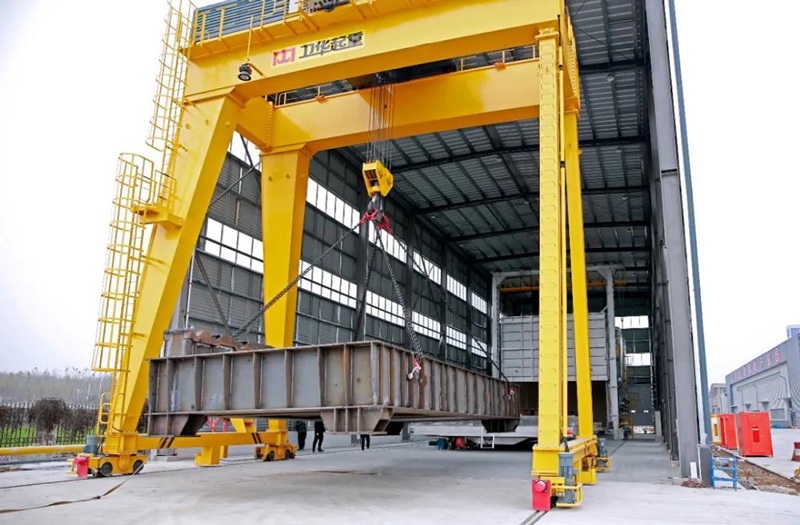

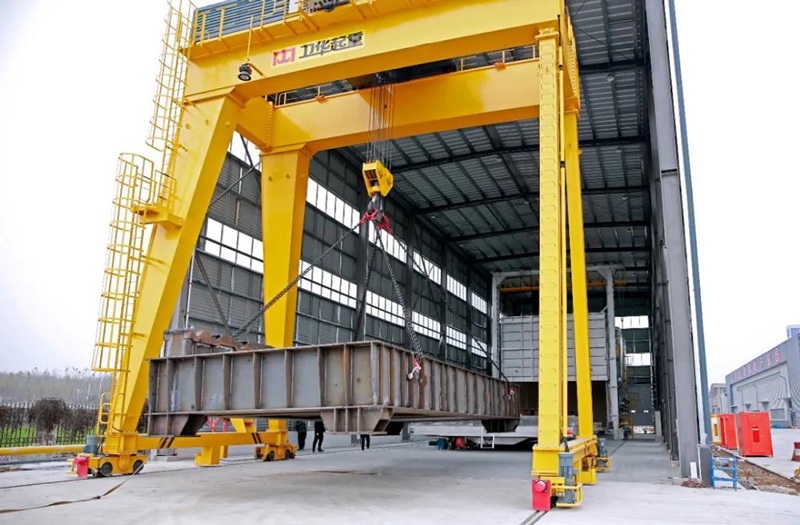

Тухайлах ялгац гишүүн 20 tons gantry crane is a heavy-duty material handling equipment designed for efficient and safe lifting operations in various industrial environments. Бат бөх барилгын ажлыг хослуулах, advanced control systems, and reliable performance, this crane is an indispensable tool for workshops, factories, агуулах, ports, and construction sites where heavy loads need to be moved with precision. It is engineered to meet the high demands of modern industrial production, ensuring stable operation, long service life, and excellent cost-effectiveness.

20 Tons Gantry Crane Technical Specifications

|

Specification Item

|

Details

|

|

Өргөх чадвартай

|

20 луу

|

|

Дээд хэмжээтэй (Distance Between Legs)

|

10м - 30м (Customizable)

|

|

Өргөх өндөр

|

6m – 20m (Customizable)

|

|

Өргөх хурд

|

3.5м / ухаан хумс (Empty), 1.75м / ухаан хумс (Loaded) (Adjustable)

|

|

Travelling Speed (Crane)

|

20m/min – 30m/min

|

|

Travelling Speed (Trolley)

|

10m/min – 20m/min

|

|

Цөсний нөөц

|

380V / 50hz / 3ph (Customizable for Different Regions)

|

|

Хяналтын арга зам

|

Pendant Control, Remote Control (Optional)

|

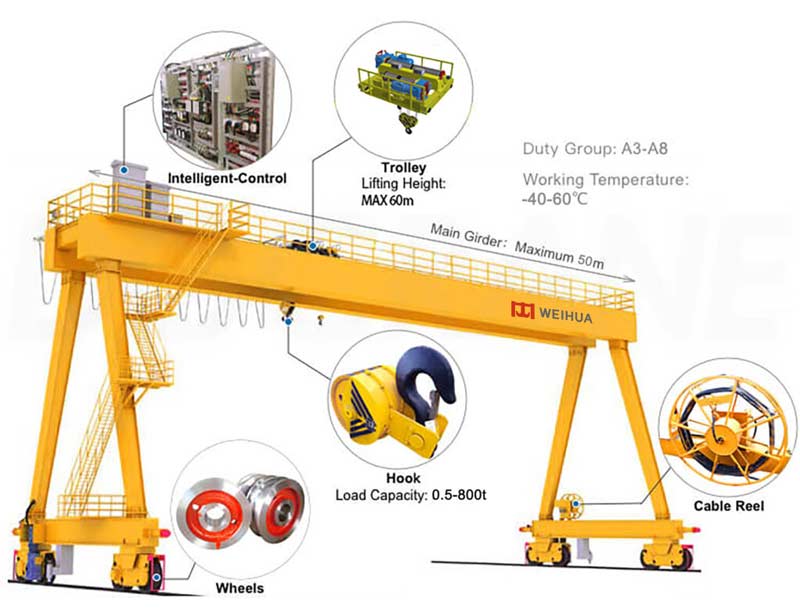

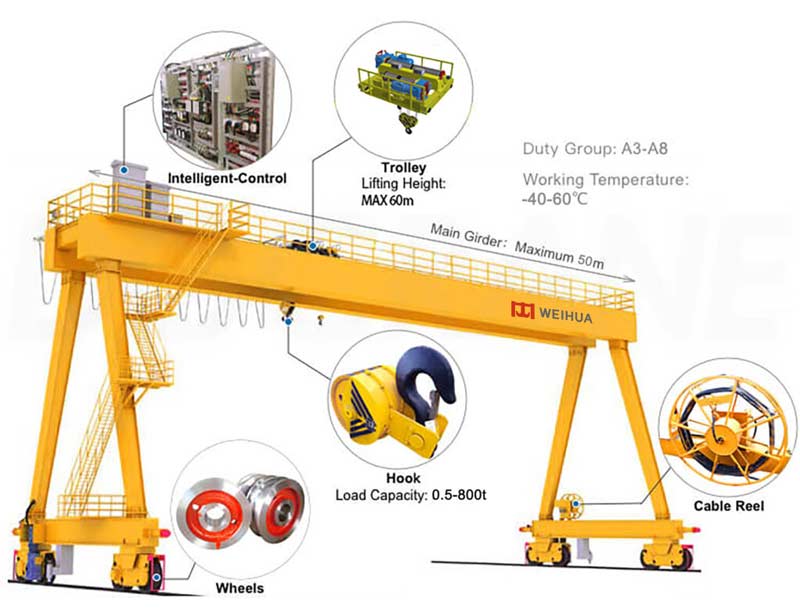

20 Tons Gantry Crane Structural Features

- 1. Robust Main Beam: The main beam is made of high-quality Q355B steel, processed through shot blasting and welding, ensuring high strength, good rigidity, and resistance to deformation. The box-type structure design enhances the load-bearing capacity and stability of the crane.

- 2. Stable Leg Structure: The legs are designed with a triangular or box-type structure, providing strong support for the main beam. They are equipped with anti-collision devices to prevent damage during operation, ensuring the safety of the Гантор Кран and surrounding equipment.

- 3. Efficient Hoisting Mechanism: The hoisting mechanism adopts a high-quality motor, reducer, and brake. The motor has high torque and low energy consumption, while the reducer ensures smooth transmission and low noise. The brake is responsive and reliable, ensuring the load can be stopped accurately at any position.

- 4. Precise Travelling System: The crane and trolley travelling systems use heavy-duty gantry crane wheels and rails, with anti-derailment devices to ensure stable and precise movement. The travelling mechanism is equipped with frequency conversion speed regulation (сайн дурын), allowing for smooth acceleration and deceleration, reducing impact on the crane and loads.

- 5. Засвар үйлчилгээ: The crane is designed with maintenance platforms and ladders, making it convenient for operators to inspect, maintain, and repair the equipment. Key components are easily accessible, Засварын хугацаа, зардлыг бууруулах.

20 Tons Gantry Crane Application Fields

Тухайлах ялгац гишүүн 20 tons gantry crane is widely used in the following fields due to its versatile performance:

- 1. Үйлдвэрлэлийн салбар: Used in workshops for lifting and moving heavy workpieces, molds, and equipment during the production process, such as in automotive, machinery, and heavy equipment manufacturing.

- 2. Warehousing and Logistics: Applied in warehouses and logistics centers to load and unload goods, stack pallets, and transfer heavy materials, improving storage and transportation efficiency.

- 3. Port and Shipping: Used in ports for handling containers, bulk cargo, and other heavy goods, facilitating the loading and unloading of ships.

- 4. Construction Site: Utilized for lifting construction materials, such as steel bars, concrete components, and construction machinery, meeting the material handling needs of construction projects.

- 5. Mining Industry: Used in mines for lifting and transporting mineral ores, equipment, and tools, adapting to the harsh working environment of mines.

20 Tons Gantry Crane Safety Performance

Safety is the top priority of our 20 тонн Гантигийн тогоруу. It is equipped with multiple safety protection devices to ensure the safety of operators and equipment.

- 1. Overload Protection Device: Automatically cuts off the power supply when the load exceeds the rated capacity, preventing overloading and potential accidents.

- 2. Limit Switch: Includes lifting height limit switch and trolley/crane travelling limit switch, preventing the crane or trolley from moving beyond the specified range.

- 3. Emergency Stop Button: Installed on the pendant control and crane body, allowing operators to stop the crane immediately in case of emergency.

- 4. Anti-Sway Device (Optional): Reduces the sway of the load during lifting and moving, improving operation stability and safety.

- 5. Insulation Protection: The electrical system is equipped with insulation protection to prevent electric shock accidents.

Gantry Crane After-Sales Service

We provide comprehensive after-sales service to ensure the smooth operation of your 20 тонн Гантигийн тогоруу:

- 1. Installation and Commissioning: Our professional technical team will send personnel to the site for installation and commissioning, ensuring the crane meets the design requirements and operation standards.

- 2. Operator Training: We offer training courses for operators, covering crane operation, safety precautions, and basic maintenance knowledge, to ensure operators can use the crane correctly and safely.

- 3. Maintenance and Repair: We provide regular maintenance services and emergency repair services. We also supply original spare parts to ensure the crane’s long-term and stable operation.

- 4. Warranty Service: We offer a 12-month warranty period from the date of commissioning. During the warranty period, we will provide free repair or replacement for any quality problems caused by manufacturing defects.

Share with PDF: Download