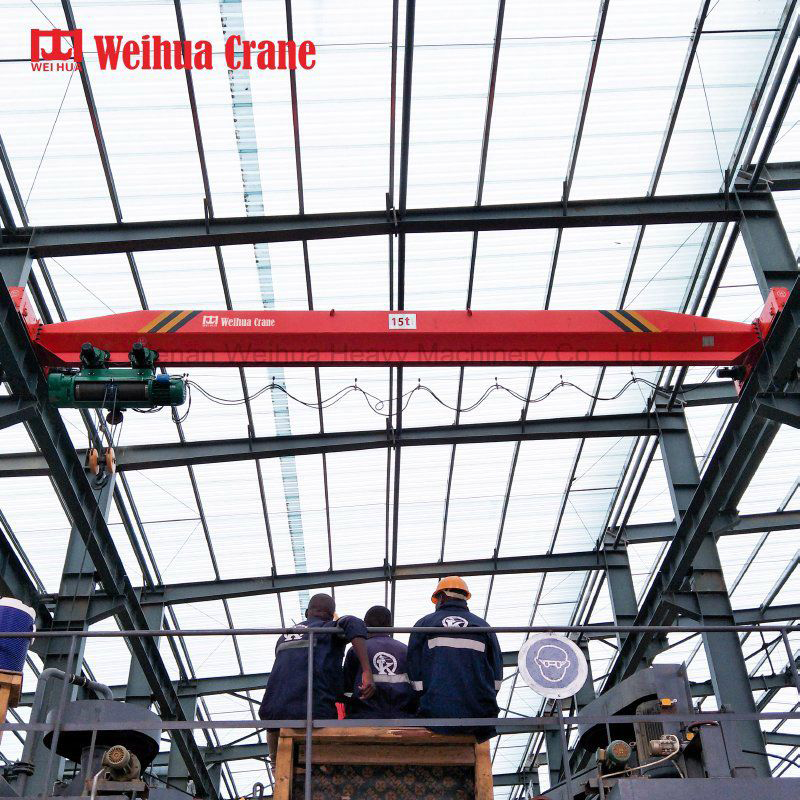

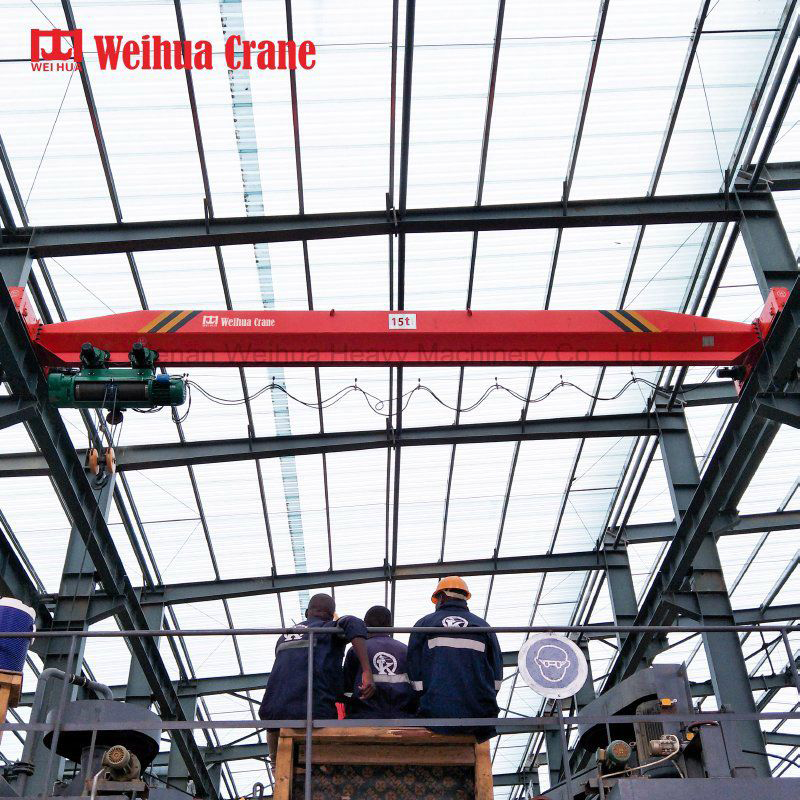

シングルガーダー天井クレーン 15 Ton

デザイン & Concept:

The single girder crane features a single bridge beam (girder) supported on two end trucks. The hoist and trolley run on the bottom flange of the girder. This design is renowned for its cost-effectiveness and ideal for applications where maximum hook height and heavy-duty, continuous service are not the primary concerns.

シングルガーダー天井クレーン 15 Ton Key Features

- 1. Cost-Efficiency: Lower initial investment due to simpler structure and reduced material requirements.

- 2. Lightweight Design: Puts less stress on the building structure, often making it suitable for existing facilities without heavy reinforcement.

- 3. Space Saving: The compact design requires less headroom, maximizing available vertical space beneath the crane.

- 4. Ease of Installation & Maintenance: Simpler structure leads to quicker installation and easier maintenance.

- 5. Versatility: Perfect for workshops, 倉庫, and manufacturing plants with standard duty cycles.

Typical Parameters Table (Single Girder – 15 Ton)

| パラメータ |

仕様 |

| 容量 |

15 トン |

| スパン (S) |

まで 30 meters |

| 揚程 |

まで 30 meters |

| Work Class |

A3 (Light to Moderate Service) |

| Controlq |

ペンダントコントロール / Radio Remote Control |

| Operating Speed |

| – Hoisting Speed |

8.0 私/私 (26.2 ft/min) |

| – Travelling Speed (Crane) |

20.0 私/私 (65.6 ft/min) |

| – Travelling Speed (Trolley) |

10.0 私/私 (32.8 ft/min) |

| 電源 |

3-段階, 400V/50Hz or 480V/60Hz |

シングルガーダー天井クレーン 15 Ton Application Scenarios

- 1. 倉庫 & Storage Facilities: For loading/unloading trucks and moving palletized goods.

- 2. Repair Shops & Maintenance Bays: Handling machinery, エンジン, and large components.

- 3. Light Assembly Lines: Moving sub-assemblies between workstations.

- 4. Steel Service Centers: Handling bundles of bar stock and sheet metal (moderate use).

Double Girder Overhead Crane 15 Ton

デザイン & Concept:

The double girder crane features two bridge beams supported by two end trucks. The hoist and trolley run on a rail mounted on top of the girders. This design offers superior performance, higher クレーンフック height, and is built for more demanding, intensive service cycles.

Double Girder Overhead Crane 15 Ton Key Features

- 1. Superior Hook Height: The top-running design provides maximum lift, as no space is taken up by the girder depth below the hoist.

- 2. Heavy-Duty & 堅牢な構造: Designed for higher duty cycles (Class A4-A7), ensuring longevity in severe service environments.

- 3. Enhanced Stability: The dual-girder structure offers exceptional load stability and reduces sway, crucial for precision lifting.

- 4. Greater Span Capability: Can be designed for much longer spans than single girder cranes with minimal deflection.

- 5. Flexibility for Attachments: Easily accommodates specialized lifting attachments like magnets, grabs, or vacuum lifters.

- 6. Cab Operated Option: Suitable for applications where the operator must have a full view from an elevated cab.

Typical Parameters Table (Double Girder – 15 Ton)

| パラメータ |

仕様 |

| 容量 |

15 トン |

| スパン (S) |

まで 35 meters+ |

| 揚程 |

まで 30 meters+ |

| Work Class |

A4-A7 (Moderate to Severe Service) |

| コントロール |

ペンダントコントロール / Radio Remote / Cab |

| Operating Speed |

| – Hoisting Speed |

8.3/0.83 私/私 (27.2/2.7 ft/min) |

| – Travelling Speed (Crane) |

32.0 私/私 (105 ft/min) |

| – Travelling Speed (Trolley) |

12.7 私/私 (41.7 ft/min) |

| 電源 |

3-段階, 400V/50Hz or 480V/60Hz |

Double Girder Overhead Crane 15 Ton Application Scenarios

- 1. Heavy Manufacturing & Fabrication Shops: Continuous handling of heavy raw materials and finished products.

- 2. Steel Mills & Foundries: Handling molten materials, large molds, and heavy slabs (often with special duty ratings).

- 3. Power Plants & Hydroelectric Dams: For maintenance of massive components like turbines and generators.

- 4. Shipyards & Ports: Assembling large ship sections and handling heavy cargo.

- 5. Paper Mills & Chemical Plants: For intensive, repetitive lifting tasks in harsh environments.

Summary & Selection Guide

| Feature |

Single Girder Crane |

Double Girder Crane |

| Initial Cost |

Lower |

Higher |

| Headroom Requirement |

Less (Lower Hook Height) |

More (Higher Hook Height) |

| Duty Cycle |

Light to Moderate (A3) |

Moderate to Severe (A4-A7) |

| Span Limitations |

Suitable for Short-Mid Spans |

Ideal for Mid-Long Spans |

| Precision & Stability |

良い |

Excellent |

| Ideal For |

Workshops, 倉庫, Occasional Use |

Heavy Industry, Foundries, Intensive Use |

Why Choose Our 15-Ton Overhead Cranes?

- 1. Custom Engineering: Every crane is calculated and designed for your specific span, height, and application.

- 2. Premium Components: We use internationally renowned hoists, モーター, and electrical systems for guaranteed performance.

- 3. Advanced Safety Features: Includes overload limiters, emergency stop buttons, end approach limit switches, and insulated systems for hazardous areas.

- 4. Full Compliance: Designed and manufactured in accordance with international standards like FEM, から, and ISO.

Contact us today to discuss your project requirements. Our engineering team will help you select the perfect 15-ton overhead crane—single or double girder—to enhance the safety and productivity of your operation.