When it comes to heavy-duty lifting and material handling, the crane gearbox plays a crucial role in transmitting power and controlling movement. It ensures that the crane performs efficiently, safely, and with the required torque. Depending on the type of crane and its specific application, different types of gearboxes are used. In this blog post, we’ll explore the most common types of crane gearboxes and their functions.

Application: Overhead cranes, gantry cranes, and jib cranes

Features:

1. High torque capacity

2. Smooth and quiet operation

3. High efficiency

Helical gearboxes are widely used in cranes due to their ability to handle heavy loads with less noise and better transmission accuracy. Their helical-cut gears ensure gradual engagement, which reduces shock loads and enhances performance.

Application: Tower cranes, mobile cranes, hoisting systems

Features:

1. Compact design with high torque output

2. Multiple gear stages

3. Excellent load distribution

Planetary gearboxes are ideal for applications requiring high torque in limited space. They use a central sun gear, planet gears, and an outer ring gear to distribute the load evenly, making them robust and efficient for demanding crane operations.

Application: Slewing systems, gantry crane rotation

Features:

1. Right-angle gear design

2. High-speed rotation capability

3. Durable construction

Bevel gearboxes are used to change the direction of drive and motion in crane systems, especially in the slewing mechanism that allows the crane to rotate. They are compact and suitable for high-speed and high-load conditions.

Application: Light-duty cranes, crane travel mechanisms

Features:

1. Self-locking mechanism

2. Cost-effective

3. Low noise operation

Worm gearboxes are commonly used in systems that require a self-locking feature to prevent back driving. Although less efficient than other types, they offer simplicity and reliability for lower-load applications.

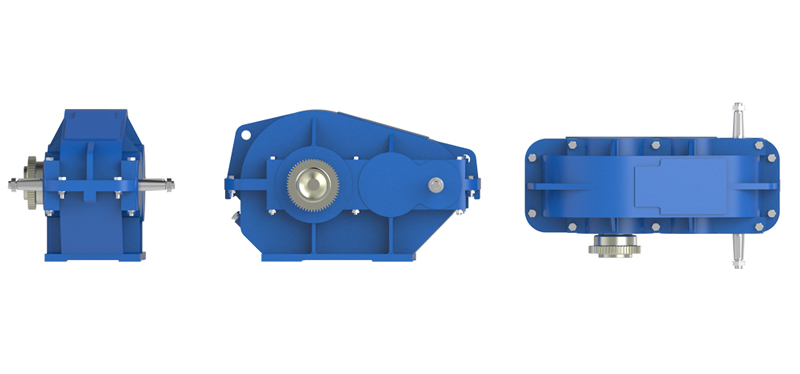

Application: Bridge cranes, trolley movement

Features:

1. Simple structure

2. High load-bearing capacity

3. Efficient power transmission

Parallel shaft gearboxes are ideal for transferring power between shafts that are parallel to each other. They are typically used in crane travel mechanisms and are known for their durability and straightforward maintenance.

Application: Specialized lifting systems, custom-engineered cranes

Features:

1. Tailored to specific project needs

2. Integrated with sensors or feedback systems

3. High customization flexibility

For unique or large-scale projects, manufacturers may design custom gearboxes with specialized gear ratios, enhanced safety systems, or integrated control features to suit unique lifting requirements.

Choosing the right crane gearbox is vital for optimizing crane performance, ensuring safety, and minimizing maintenance downtime. Whether you’re dealing with an overhead crane in a warehouse or a mobile crane on a construction site, understanding the gearbox type helps in proper selection, operation, and maintenance.

If you’re in the market for high-quality crane gearboxes or looking to upgrade your current system, make sure to consult with a reliable crane equipment manufacturer that can provide expert guidance and tailored solutions.

Laissez votre commentaire ici