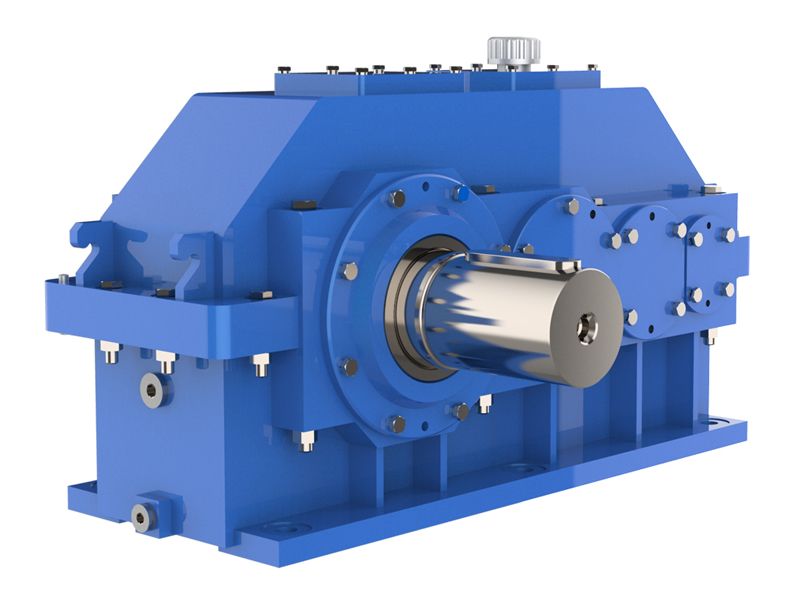

Weihua Caja de cambios para grúa puente es un componente central diseñado para ofrecer precisión, poderoso, y movimiento fiable para puentes grúa eléctricos (Grúas puente). Diseñado con tecnología de engranajes avanzada y construido con materiales de alta calidad., Esta caja de cambios garantiza un rendimiento duradero y un funcionamiento suave incluso en condiciones industriales de servicio pesado..

| Parámetro | Gama de cajas de cambios de polipasto | Gama de cajas de cambios de viaje con carro | Notas |

| Clasificación de potencia | 3 kilovatios – 400 kilovatios | 1.5 kilovatios – 90 kilovatios | Dependiente del ciclo de trabajo (FEM 1M a 4M) |

| Par de salida (Nominal) | 1,000 nm – 200,000 Nuevo Méjico | 500 nm – 30,000 Nuevo Méjico | Capacidad de par máximo 2,5× nominal |

| Relación de reducción (i) | 10:1 - 200:1 | 5:1 - 80:1 | Proporciones personalizadas disponibles |

| Eficiencia | 94% - 98% | 92% - 96% | Diseño de engranaje helicoidal/endurecido |

| Velocidad de entrada | 750 / 1,000 / 1,500 / 1,800 RPM | 750 / 1,000 / 1,500 RPM | Compatible con motores IEC |

| Tipo de montaje | Montado con pies, Montado en brida (B5/B14) | Montado con pies, Montado en brida | Opciones montadas en eje para carros |

| Tipo de engranaje | Helicoidal / Helicoidal endurecido (Serie HG) | Helicoidal / Helicoidal endurecido | Serie HG: Cementado (CDH 58-62) |

| Material de la carcasa | Hierro fundido (GGG50) / Acero soldado | Hierro fundido / Acero soldado | Estándar de protección IP55 |

| Lubricación | Aceite sintético para engranajes EP (ISOS VG 150-320) | Aceite sintético para engranajes EP (ISOS VG 100-220) | Lubricación por salpicadura + rodamientos sellados |

| Temperatura de funcionamiento. | -20°C a +80°C | -20°C a +80°C | Enfriamiento forzado disponible para >80°C |

| Factor de servicio | 1.25 - 2.0 (para FEM/ISO) | 1.1 - 1.6 (para FEM/ISO) | Basado en FEM 1.001/ISO 6336 |

| Reacción | ≤ 120 arcomin (PAG < 100 kilovatios)

≤ 100 arcomin (PAG ≥ 100 kilovatios) |

≤ 100 arcomin | Rectificado con precisión para una marcha atrás suave |

| Nivel de ruido | ≤ 75 dB(A) @ 1 m de distancia | ≤ 70 dB(A) @ 1 m de distancia | Medido bajo carga completa |

| Factor de seguridad (Doblar) | ≥ 2.0 | ≥ 1.8 | Femenado 1.001 / AGMA 2001-D04 |

| Factor de seguridad (Contacto) | ≥ 1.5 | ≥ 1.4 | |

| Cumplimiento de estándares | ISO 6336, Femenado 1.001, DE 3990, AGMA 6010 | ISO 6336, Femenado 1.001 | Certificaciones CMAA/AS bajo petición |

1. Serie helicoidal estándar

Aplicaciones: Grúas de taller generales, almacenes.

máx.. Esfuerzo de torsión: 50,000 Nuevo Méjico (izar), 15,000 Nuevo Méjico (carretilla).

2. Helicoidal endurecido (hg) Serie

Aplicaciones: acerías, fundiciones, minería.

Dureza superficial: CDH 58-62.

máx.. Esfuerzo de torsión: 200,000 Nuevo Méjico (izar), 30,000 Nuevo Méjico (carretilla).

3. Soporte de personalización

| Tamaño del modelo | Peso (kg) | Diámetro de brida. (mm) | Diámetro del eje de salida. (mm) |

| Pequeño (≤30kW) | 50 - 200 | 200 - 400 | 40 - 80 |

| Medio (≤160kW) | 250 - 900 | 450 - 800 | 90 - 160 |

| Grande (≤400kW) | 1,000 - 4,500 | 850 - 1,500 | 180 - 300 |

Notas:

1. Ciclo de servicio: Diseñado para FEM 1M (luz) son 4M (deber severo).

2. Compatibilidad de la unidad VF: Optimizado para motores accionados por inversor (5-100 Hz).

3. Pruebas: 100% probado bajo carga; Análisis de vibraciones según ISO. 10816.

4. Plazo de entrega: 15–30 días para modelos estándar; 45–60 días para unidades personalizadas.

Weihha Cajas de cambios para grúa puente no son solo componentes; Son sistemas de transmisión de potencia de precisión construidos para manejar las rigurosas demandas de:

1. Alto par de arranque para levantar cargas pesadas sin problemas.

2. Ciclos frecuentes de arranque y parada inherentes a la operación de la grúa..

3. Velocidades variables y control de posicionamiento preciso.

4. Exposición al polvo, humedad, y fluctuaciones de temperatura.

1. Construcción robusta & Materiales de primera calidad: Fabricado con aceros aleados de alta resistencia para engranajes y ejes., alojado en rígido, Carcasas de hierro fundido de alta calidad o de acero soldado.. Esto garantiza una resistencia excepcional a las cargas de impacto., momentos de flexión, y usar.

2. Helicoidal avanzado / Engranaje helicoidal endurecido: Nuestro diseño de engranaje helicoidal estándar proporciona un, funcionamiento más silencioso y mayor eficiencia de transmisión de par en comparación con los engranajes rectos. Para máxima durabilidad en condiciones extremas, Weihua ofrece engranajes helicoidales endurecidos y rectificados, aumentando significativamente la dureza de la superficie y la vida útil.

3. Transmisión de potencia optimizada & Eficiencia: Los perfiles de dientes diseñados con precisión y la fabricación meticulosa minimizan la pérdida de energía., lo que se traduce en un menor consumo de energía y costos operativos reducidos durante la vida útil de la grúa.

4. Sellado superior & Lubricación: Sistemas de sellado multicapa (sellos de labios, sellos laberínticos) Previene eficazmente las fugas de lubricante y la entrada de contaminantes.. Los canales de lubricación optimizados garantizan que todos los componentes críticos estén adecuadamente lubricados., incluso bajo cargas pesadas y pendientes.

5. Alta confiabilidad & Vida útil extendida: Riguroso control de calidad, simulación de diseño avanzado (Fea), y estrictos protocolos de prueba garantizan una confiabilidad excepcional. Las cajas de cambios Weihua están diseñadas para durar, Minimizar el tiempo de inactividad no planificado y los costos de mantenimiento..

6. Liso & Operación silenciosa: El diseño del engranaje helicoidal combinado con el mecanizado de precisión da como resultado niveles de vibración y ruido significativamente reducidos., contribuyendo a un mejor ambiente de trabajo.

7. Integración integral de seguridad: Diseñado como un componente de seguridad crítico, Nuestras cajas de cambios contribuyen al funcionamiento seguro general de la grúa., Garantizar el movimiento controlado y la manipulación de la carga en todas las condiciones especificadas..

8. Cumplimiento de estándares: Diseñado y fabricado para cumplir o superar los estándares internacionales relevantes para la seguridad y el rendimiento de las grúas. (como ISO, Femenado, DE, CMAA, COMO).

9. Amplia personalización: Weihua entiende que cada aplicación es única. Ofrecemos soluciones personalizadas de cajas de cambios para grúas puente adaptadas a requisitos específicos, incluido:

Varias relaciones de reducción

Múltiples configuraciones de montaje (montado en los pies, montado en brida)

Tamaños y tipos de ejes de entrada/salida

Clasificaciones de potencia y par específicas

Integración con diferentes tipos de motores. (P.EJ., inducción de CA, compatible con variador de frecuencia)

Weihha Cajas de cambios para grúa puente son componentes integrales que impulsan tanto el mecanismo de elevación (levantar/bajar la carga) y el mecanismo de desplazamiento del carro (moviendo el polipasto a través del puente) en diversos entornos:

Fábricas de acero & Fuseles

Plantas de energía

Astilleros

Minería & cantera

Fabricación de maquinaria pesada

Almacenes & Centros de logística

Puerto & Terminales

Sitios de construcción

1. Experiencia probada: Décadas de experiencia dedicada en ingeniería de grúas.

2. Integración vertical: Control sobre el diseño, abastecimiento de materiales, fabricación, y las pruebas garantizan una calidad constante.

3. Red de soporte global: Acceso al soporte técnico, repuestos originales, y servicio en todo el mundo.

4. Centrarse en el valor: Ofreciendo el equilibrio óptimo de rendimiento, durabilidad, y costo total de propiedad.

Invierta en la potencia de su grúa.

Elige Weihua Cajas de engranajes para grúa EOT – el confiable, eficiente, y solución duradera diseñada para mantener sus operaciones de elevación por encima de la cabeza funcionando sin problemas y de manera productiva, día tras día.

Deja tu comentario aquí